Oxygen Plants

Liquid Nitrogen Plants

Argon Production

Hydrogen Systems

Filling Systems

-

Operation & Maintenance Services

Integrated solutions provider for plant operation, maintenance, process design, installation, commissioning, reconditioning, AMC services, equipment audit, EPC consulting, efficiency enhancement, and cost reduction for oxygen plants.

-

Installation & Commissioning

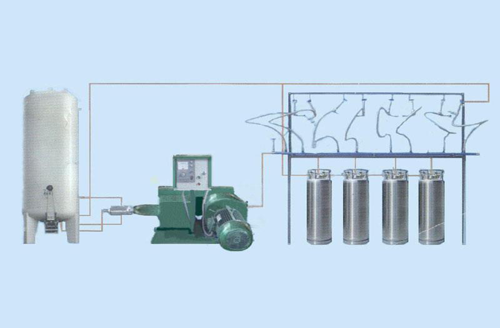

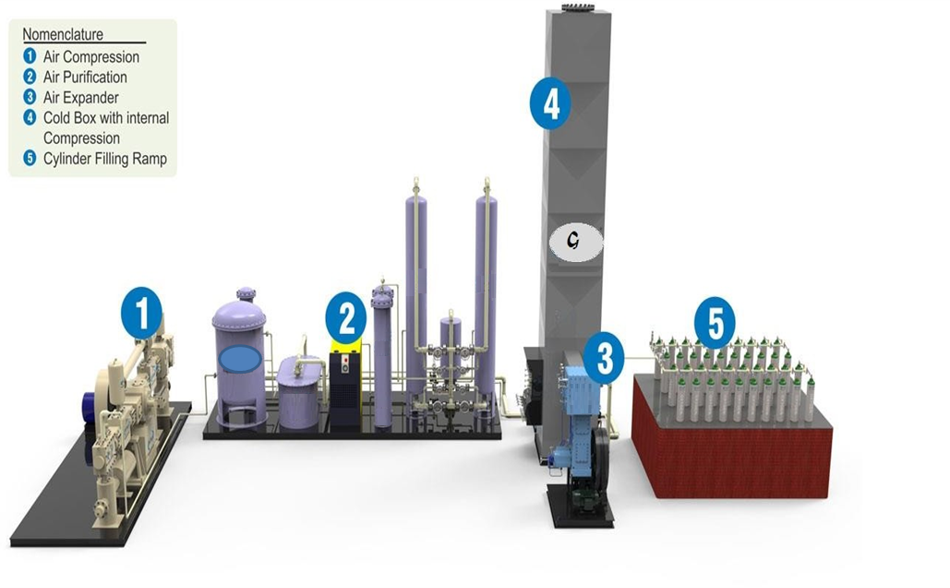

We can offer Complete solutions for Installation & Commissioning for the Plant ranges from mini sizes of 100 m3/hr to Tonnage sizes of 300TPD or more, we have all expertise to study and analyze the engineering to meet your requirement. We have also the solutions for small size conventional type reciprocating expander and compressors.

-

Design & Development

Designing machinery involves crafting blueprints with innovation, while development focuses on refining prototypes for reliable and efficient equipment.

Welcome to Global Cryogenic Corporation

One stop Solution for Clean Energy & Gas Plants

We deal with services & engineering for Plant ranges from mini sizes of 100 m3/hr to Tonnage sizes of 300TPD or more, we have all expertise to study and analyze the engineering to meet your requirement. Our successful Installation and support have proven in so many countries.

Oxygen Plants

Liquid Nitrogen Plants

Argon Production

Hydrogen Systems

Filling Systems

Large Capacity Oxygen & LNG Plant

Liquid / Gas Filling Stations

Small Capacity Plant for Cylinder Filling

LNG Metering Skid

We are Global Cryogenic Corporation

Our Services

Operation & Maintenance of Plants

Installation & commissioning

Design & Development for Machinery

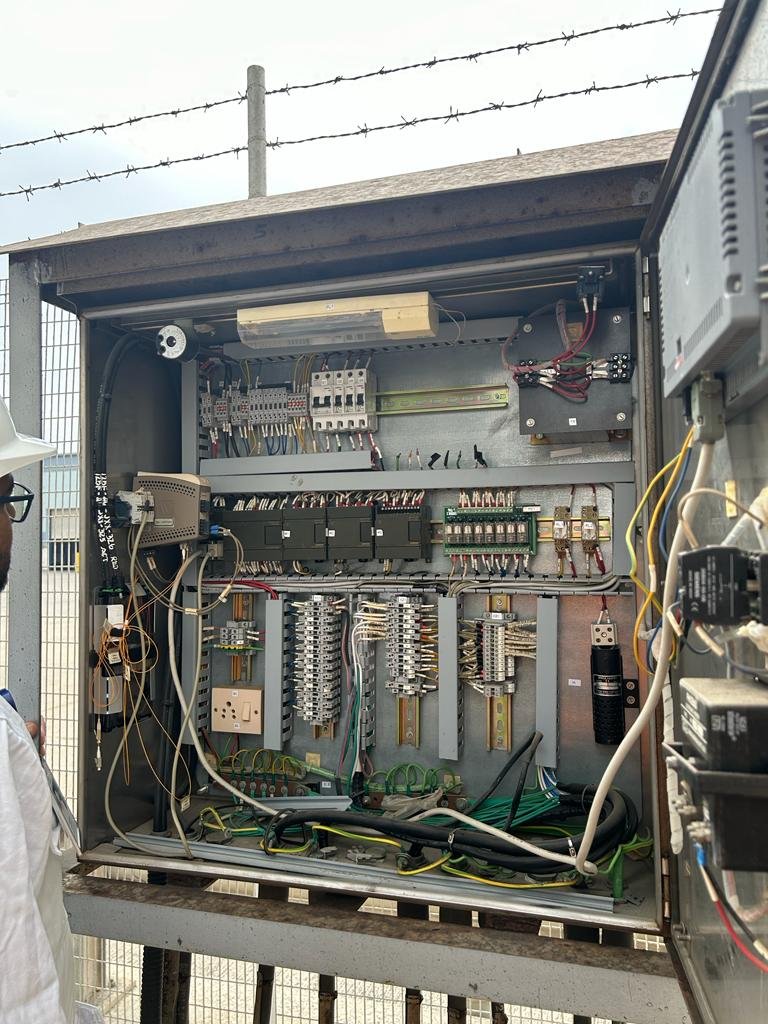

Process Automation & Control System Development for Machinery

EPC & Consultancy for new Projects

Spare Parts supply by providing and easy online purchase option

Mobile App for cylinder supply monitoring

Training & Staffing for plants

Why Choose Professionals?

Operational Mastery

Operational Skill is the key point of operation of Air separation plant to achieve high purity of products, higher efficiency & smooth operation.

Maintenance Expertise

Equipment of oxygen plant needs balanced operation & preventive maintenance by expert hands to maintain healthy condition.

Performance Impact

In case of poor maintenance & wrong operation plant consumes power but production & quality goes down and as many times plant is stopped for maintenance . Huge power is loss without production.

Safety Optimization

Filling & storage system. Cryogenic gas supply through pipeline or cylinder filling station but in many cases heavy loss of gases and hazardous accident took place. Proper design analysis & maintenance of these system should be done to prevent these losses.

Our Industry Experts Can Solve Your Plant Issues

Why choose professionals

- Loss of product purity

- Increasing production cost

- Unsatisfied by equipment performance

- Machine quality need improvement

- Efficiency going down

- Want Automatic control & monitoring system

- Power consumption cost is going high

- Worried about maintenance

- Planning to buy new equipment

- Bothered to select equipment's & spare parts

- Facing losses due to breakdown

- Losses due to wrong operation in plant

- Unsatisfied by OEM response

Industry We Serve

Oil & Gas

Aerospace & Aviation

Medical Application

Food & Beverages

Industrial Gases

Recent Projects

Liquid Nitrogen Project In Doha Qatar LNG Company.

Liquid Nitrogen Production Setup In LNG Company Africa.

12 Tons per day Oxygen Production within a Record time of 20 days in Bangladesh

PLC Control System Production & Storage Monitoring

Plant started producing gas oxygen, saving cost & reduced energy consumption